There are actually conditions in which TLC screening, Along with chemical analyses, might be wanted. Inside of a bulk course of action, specifically for extremely powerful chemical compounds like some steroids, The problem of by-items must be thought of if gear isn't committed. The objective of the inspection is making sure that the basis for any limits is scientifically justifiable.

Services that employ these Sophisticated aseptic processing methods are presently in Procedure. In amenities exactly where personnel have already been totally excluded within the vital zone, the necessity for room classification determined by particulate and environmental microbiological checking prerequisites may very well be significantly reduced.

Zone defines the general character - whether it is a gas or dust - plus the chance of hazardous materials currently being present within an ignitable concentration during the surrounding ambiance. The Zone system has three levels of hazard for fuel or dust in which the Division program has two.

In the event of pressurized units the enclosure is supplied with a protecting fuel which include dry instrument air or nitrogen to take care of a pressure a little bit greater than atmospheric force, and this can reduce the entrance of the flammable gasoline or vapor or even a combustible dust Within the enclosure.

FDA expects the final validation strategies to deal with that's chargeable for performing and approving the validation research, the acceptance criteria, and when revalidation are going to be essential.

Environmental microbial monitoring and Examination of knowledge by skilled staff will permit the status of Management for being taken care of in clean rooms together with other managed environments.

On this page we will go over the examples of classified & non classified areas combined with the important difference between classified & non classified areas.

In much larger devices, including those using extended transfer strains or piping, Test the stream charts and piping diagrams for the identification of valves and published cleaning processes.

Different media to These stated may be used offered that they're validated for that purpose meant.

Moreover, the focus of microorganisms within the natural environment is monitored; Every single Cleanliness Class defined is likewise assigned a microbial amount for air, surface, and personnel gear.

Managed Environment—Any area in an aseptic process technique for which airborne particulate and microorganism ranges are managed to specific stages, acceptable to the things to do conducted inside that environment.

The first step should be to focus on the objective from the validation procedure, and Now we have noticed that some firms have did not establish these kinds of objectives. It truly is not unusual to discover manufacturers use intensive sampling and tests packages following the cleaning process without at any time really assessing the performance from here the steps used to clean the tools. Numerous inquiries need to be tackled when evaluating the cleaning approach. For instance, at what issue does a piece of apparatus or process become clean?

Ascertain the specificity and sensitivity of the analytical approach accustomed to detect residuals or contaminants. With advancements in analytical technologies, residues with the producing and cleaning procedures is often detected at pretty low ranges. If levels of contamination or residual aren't detected, it does not imply that there is no residual contaminant current soon after cleaning. It only signifies that levels of contaminant higher as opposed to sensitivity or detection limit in check here the analytical system are usually not existing from the sample.

In the event of purged techniques, the enclosure is supplied that has a protective fuel which include dry instrument air or nitrogen at an appropriate pressure and stream price and this will decrease the focus of any flammable gas or vapor Which may be at first existing to a stage that it'll not help an explosion. The enclosure is purged before beginning the gear.

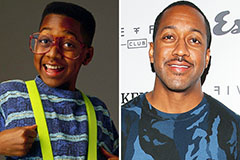

Jaleel White Then & Now!

Jaleel White Then & Now! Alicia Silverstone Then & Now!

Alicia Silverstone Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now!